Simple yet highly strategic, pallets are a fundamental element of modern logistics. From production to storage, and from handling to international shipments, the correct use of pallets makes it possible to optimize space, time, and costs while reducing the risk of cargo damage.

In this guide by Savino Del Bene, we take an in-depth look at what pallets are, the most common pallet dimensions, how much a pallet weighs, the different pallet types available, and how pallets impact shipping, with a practical focus on palletization and container loading.

What is a pallet and why it is so central to modern logistics

A pallet is a standardized platform designed to facilitate the handling, storage, and transportation of goods throughout the supply chain. Its value lies not only in its supporting function, but also in its ability to standardize logistics flows, making them compatible with mechanized handling systems and global transport infrastructure.

From an operational perspective, it is essential to distinguish between:

- Package (or carton): the individual piece of packaging containing the goods;

- Pallet: the base on which one or more packages are placed;

- Unit load: the load unit resulting from the combination of pallet and secured, stabilized goods.

This distinction is crucial because most logistics processes – such as pricing, stowage, handling, and insurance – refer to the unit load rather than the individual package. Pallets enable the efficient use of forklifts, manual and electric pallet trucks, automated warehouses, and picking systems, reducing handling times and improving workforce safety.

In the context of international freight services, pallets also act as an interface between the warehouse, the means of transport, and the container, ensuring operational continuity across the different stages of the logistics chain.

Pallet dimensions: the most commonly used formats

Pallet dimensions are a key factor in space optimization and compatibility with transport equipment. There is no single global standard, but rather a set of consolidated formats designed to meet regional and industry-specific requirements.

EPAL / EUR pallets

The EUR pallet (EPAL) is the European standard par excellence. Its dimensions of 1200 x 800 mm make it ideal for:

- Transport on European trucks and semi-trailers;

- Storage in warehouses with standard racking systems;

- Optimized loading in ocean containers.

The widespread use of EPAL pallets ensures interchangeability, controlled quality, and broad acceptance throughout the European supply chain.

Main ISO pallet formats

Outside Europe, various ISO pallet formats are used, designed to fit local infrastructure and specific markets. The most common include:

- 1200 x 1000 mm, widely used in the UK, Asia, and some industrial sectors;

- 1140 x 1140 mm, typical of the Australian market;

- 1100 x 1100 mm, also widely used in Asia;

- 1219 x 1016 mm, the North American standard.

The choice of pallet format directly affects container utilization, the number of pallets that can be loaded, and cargo stability during transport.

Pallet weight and load capacity: what to consider

When discussing pallets, the issue of weight must be addressed on several levels. What matters is not only how much an empty pallet weighs, but also how its weight affects overall load capacity and the limits imposed by transport equipment.

Indicatively:

- a wooden EUR pallet weighs between 20 and 25 kg;

- plastic pallets can be lighter, but with varying load capacities;

- metal pallets are heavier, but suitable for extreme loads.

From a technical standpoint, pallet load capacity is divided into:

- Static load: when the pallet is stationary on the ground;

- Dynamic load: during handling with a forklift;

- Racking load: when the pallet is stored in warehouse racks.

This distinction is essential in international shipments, where overloaded or unsuitable pallets can lead to cargo damage, safety issues, or load rejection by carriers.

Types of pallets: materials, structures, and use cases

Pallet types mainly differ in terms of construction material, structural design, and intended use—three factors that directly affect costs, safety, regulatory compliance, and transport methods. Choosing the right pallet is never a neutral decision: it impacts handling efficiency, cargo integrity, and acceptance throughout the logistics chain.

Wooden pallets

Wooden pallets are the most widely used solution worldwide. They are valued for their low cost, good load capacity, and ease of repair. They are used across most industrial and commercial sectors; however, for extra-EU international shipments, they must comply with ISPM-15 regulations, which require specific phytosanitary treatments. This aspect is particularly relevant, as non-compliance can lead to customs detentions or rejection of the cargo.

Plastic pallets

Plastic pallets offer high dimensional consistency, resistance to moisture, and do not require phytosanitary treatment. For these reasons, they are often preferred in the pharmaceutical, food, and chemical sectors, as well as in air freight shipments, where pallet weight has a significant impact on costs. Their main limitation is the higher initial cost, which makes them less suitable for one-way flows or occasional exports.

Metal pallets

Metal pallets are used in specific contexts that require high load capacity and maximum robustness, such as the transport of machinery, heavy industrial components, or out-of-gauge cargo. They are mainly employed in closed logistics loops or project cargo operations, where reusability and structural strength offset the higher weight and cost.

Single-use pallets (export pallets)

Alongside these solutions, there are single-use or export pallets, designed for low-cost international shipments with no need for return. They are often used for lightweight goods or occasional flows and help reduce initial investment, although they offer lower load capacity than standard pallets.

From a structural perspective, pallets can be two-way or four-way, depending on forklift access. Four-way pallets provide greater operational flexibility in warehouses and during loading and unloading operations, while two-way pallets are generally more economical but less versatile.

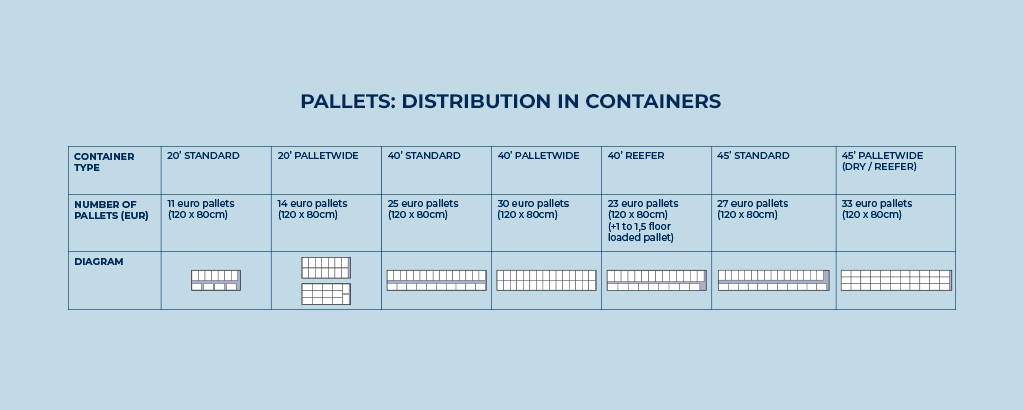

How many pallets fit into a container

One of the most relevant aspects in shipment planning—since it affects costs, load utilization, and logistics efficiency—is determining how many pallets fit into a container.

The number of pallets that can be loaded does not depend on a single factor, but on a combination of technical and operational variables. First of all, pallet format plays a key role. In addition, the type of container used and the overall height of the unit load can limit or expand stowage options.

Indicatively, using EUR pallets:

- a 20-foot container can hold approximately 11 pallets on a single level;

- a 40-foot container can accommodate around 23–24 pallets;

- a 40’ High Cube container allows the same number of pallets but offers greater usable height for taller unit loads;

- a 45-foot container can hold up to 27 pallets.

Beyond the theoretical figures, loading layout must also be considered. Longitudinal or transverse arrangements, the need for safety corridors, and the presence of fragile or out-of-gauge cargo can reduce the actual number of pallets loaded. In addition, total cargo weight may represent a further constraint, especially for dense goods.

For this reason, load planning is often supported by loading plans and stowage simulations, which help optimize available space, reduce cost per pallet shipped, and prevent issues during transport and unloading.

Palletization: how to optimize it

Palletization is a critical phase that directly affects cargo safety and integrity. It is not simply a matter of placing packages on a pallet, but of creating a stable, compact load unit that complies with transport requirements.

Key best practices include:

- Distributing weight evenly;

- Respecting height and load limits;

- Using appropriate securing systems (stretch film, strapping, corner protectors);

- Avoiding overhangs that could compromise stability;

- Adapting palletization to the transport mode (container, truck, aircraft).

Optimized palletization reduces damage, claims, and unexpected costs throughout the supply chain.

Conclusion

Pallets are a key element for the efficiency of logistics and international shipments. Understanding pallet dimensions, weight, types, and load capacity enables more informed decisions and helps optimize the entire supply chain. For your ocean and air freight services, relying on an experienced freight forwarder like Savino Del Bene means benefiting from qualified support in choosing the most suitable solutions for your business needs. Contact your local representative for a personalized consultation.